Enhancing Experience, Intuition and Guts

In their 2011 book on Daily Management, Ando and Kumar discuss problem-solving that aims to improve process performance. (Daily Management the TQM Way: The Key to Success in Tata Steel, Productivity and Quality Publishing Pvt. Ltd, Madras).

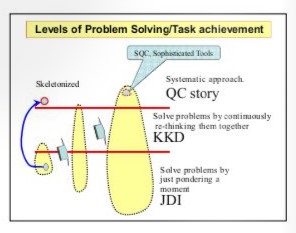

The picture at the top of this post shows three types of problem solving: JDI, KKD, and QC Story (p. 139 and also in a presentation available here, accessed 12 July 2017.)

Let’s interpret the acronyms and explore a few implications.

JDI: Just Do It Improvement

“Many improvements are effected in the process on a daily basis. Answers to many of the abnormalities or problems can be found by just pondering over and analyzing the situation. These answers are enough to prevent recurrences. These actions can be done by ‘Just Do It (JDI)’ approach. You should not hesitate to take this approach. If you have confidence on your understanding of the cause of the abnormalities and the effect of the action taken, why do you need to hesitate?” (p. 138, Ando and Kumar).

My colleagues at API recognized JDI in Table 7.1 of The Improvement Guide, 2nd edition, discussed previously in this post and this post.

According to API, you can safely "just do it” if you meet three conditions: you have strong degree of belief that your idea will work, there’s low cost of failure and a strong commitment of the organization to embrace the change.

(Table 7.1 G. Langley et al. (2009), The Improvement Guide, 2nd edition, Jossey-Bass, San Francisco © Associates in Process Improvement)

KKD: Keikan, Kan, Dokyu--Experience, Intuition, Guts

“Some improvements however cannot be effected only by the JDI approach. To address some abnormalities, you may need to summon help from outsiders who are familiar with these problems—engineers or consultants—for advice.”

“In other words, you can take action based on your own experience, intuition, and guts!”

Ando and Kumar also say that KKD solutions may emerge from discussion by team members, as you tap the knowledge of people doing the work as well as experts.

The QC Story

The QC Story is an elegant seven-step method to document improvement. It is a guide to careful and disciplined problem-solving, similar to DMAIC in Six Sigma or the A3 method in Lean. The best reference in English is Chapter 10 “QC Story” in H. Kume Introduction to Statistical Methods for Quality Improvement (1985), AOTS: Tokyo.

As Ando and Kumar point out, effective organizations nurture JDI and KKD problem-solving. On the other hand, “… some not-so-smart companies de-emphasize these incremental improvement activities, and try hard to promote only high-level improvement activities [i.e. QC Story].” (p. 140).

My colleagues and I fell into that trap in the late 1980’s: we focused exclusively on QC Story as the way to improve performance and were infatuated by the application of structured QC data tools.

The Model for Improvement as a bridge between JDI and QC Story

Ando and Kumar’s picture shows an evolution of problem-solving. The left side shows undeveloped problem solving, dominated by JDI.

In the middle, people are now applying KKD as well as JDI.

In the most advanced state, on the right, there are many more problems being solved. People mostly use JDI and KKD; sometimes they use the systematic approach of the QC Story. Even more rarely, they apply statistical quality control methods, which are best for particularly persistent or important problems not solved by JDI or KKD.

How can organizations move toward the advanced state? Get better at KKD!

Enhanced KKD problem-solving sets the stage for selective use of structured problem-solving and encourages more extensive JDI problem-solving.

Here’s one way to get better at KKD problem-solving: Use the Model for Improvement.

The Model for Improvement is a guide that can be used both as a heuristic and an outline for disciplined improvement. Here’s how you can get better at KKD using the Model for Improvement. You always ask the three questions about aims, measures, and changes and then use Plan-Do-Study-Act cycles to test your ideas, confirming or disconfirming. Testing changes develops intuition and builds experience, “learning by doing”. Success with improvements builds confidence. You’ll be more ready to make a change as you practice making changes--stronger “guts.”

Appendix: More insights from Ando and Kumar (pp. 138-140)

1. “If you can take appropriate action using the JDI or KKD approaches and resolve the problem, you need not use the QC Story procedure.”

2. “The ratio of improvements effected by JDI, KKD and QC Story are as follows: JDI : KKD : QC Story = 300 : 30 : 1.”

3. “Sometimes, some not-so-smart companies de-emphasize these incremental improvement activities, and try hard to promote only high-level improvement activities.”

4. “Please note that improvements by the JDI are hardly possible if the mood of improvement is not established at the site. Improvements by KKD will need opportunities to consider solutions with other members. However some people look down upon these kinds of activities as ‘low level’ and pay attention only to ‘Significant improvement done by the QC Story.’”

5. “It is advisable to encourage activities at the JDI or KKD level by accepting them as they are. When such an organizational culture is nurtured, the QC Story approach can be applied for difficult and chronic problems and challenges and it will yield big results.”